Sports Goggles can withstand the hottest of desert & most chill of mountain weather conditions, keep your view clear, and protect your face from dirt, snow, water, etc. Every Rider & Skier can not imagine living without them.

If you are a sports enthusiast and a curious person who dives into details or a person who is just curious about what they are made of, then you have to the right spot. Because in this blog, we will break the Goggles into 5-main parts, and study each in detail, which are;

- Lens

- Frame

- Foam Padding

- Anti-Fog Coating

- Strap

- Tear-Off / Roll off

1) Lens

Lenses are the most essential part of any Goggles, whether a motocross or snow one. In reality, all the other parts of goggles are just there to keep the Lenses in their place. Lenses save the eyes from upcoming snow, dirt, wind, tree twigs, stones, or any form of debris, so they must be sturdy. Lenses also keep our view clear by not fogging up.

Goggles Lenses ( including tear-off posts ) are made from 2-kinds of materials;

- a) Cheap Plastic

- b) Premium Resins

a) Cheap Plastic

Some sellers use cheap plastic like PVC to make their Goggles lenses.

➔ Pros:

- Inexpensive

- Blocks some snow & dust

- Protecting your eyes against wind

➔ Cons:

- Short life span.

- Shatters if hit by something hard and can damage the eyes.

b) Premium Resins

Professional manufacturers use one of the following materials in the Goggle lens, such as;

- Polycarbonate

- Polyacrylate

- Polyamide

- Polyester

- Cellulose

- Polyester-urethane

- Polyether-urethane

Among these materials, Polycarbonate, also known as Trivetic or Trivex due to its extreme resistance to cold & and impacts, is used by most producers. Almost all sellers use polyester to make tear-offs films. If you wanna know how polarized lenses are manufactured, then click here.

➔ Pros:

- Provides all levels of superior protection against wind, dust, mud, stones, etc.

- Bond well with anti-fog, UV, Tinting, and other coatings.

- Have a clear view and produces less vision distortion.

- Scratch resistant

2) Frame

The frame is the part that keeps the lens in its place and saves eyes from the fast wind. As frames always stick close to the face, so it has to be flexible to bend with facial features, and in case of an accident, it does not cause any harm.

Manufacturers can use two types of bike & ski goggles material to make their Goggles frame;

a) Hard Plastic

b) Flexible TPU

a) Hard Plastic

Some cheap manufacturers use hard plastic materials like polyester, polyether, polystyrene, polyethylene, vinyl, etc., to earn more profits without considering user safety.

➔ Pros:

- Inexpensive

➔ Cons:

- Uncomfortable to wear.

- An accident can severely damage the face, eyes, or head.

b) Flexible TPU

TPU, also known as Thermoplastic Polyurethane, is a very famous material for making Goggles frames. Almost all favorite brands and top-notch manufacturers preferred this material.

➔ Pros:

- Superior flexibility; it’s safe, fits different faces ideally, and is comfy.

- Have resistance against extreme hot & cold temperatures.

- It can last for years.

➔ Cons: costly

3) Foam Padding

Foam padding provides a soft and flexible layer between the face & goggles. Wearing goggles is almost impossible without them because, during riding, the goggles will move and bruise the face.

Mostly 3-layers of foam are used; the first 2-layers absorb the shocks, while the 3rd innermost layer provides a soft area for the face.

Foam padding is mainly made out of one of these materials;

- Polyester

- Polyether

- Polystyrene

- Polyurethane

- Polyethylene

- Vinyl

➔ Pros:

- Provides Comfortness

- Give a more seal-proof fit on different faces.

- Protect face from hard frame bruises.

➔ Cons: None

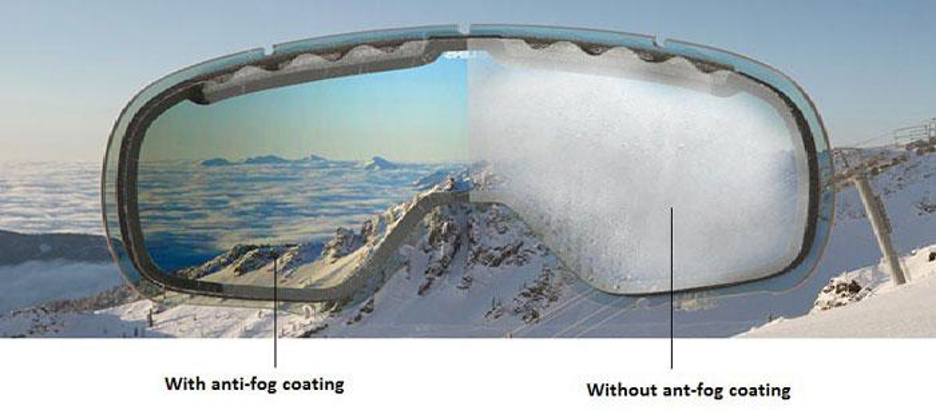

4) Anti-Fog Coating

Ski and Motocross goggles have an Anti-fog coating inside and outside of the lens to keep moisture from building up on the lens and maintain a clear view. There are two types of Anti-Fog Coatings;

- a) Hydrophilic

- b) Hydrophobic

a) Hydrophilic

The “Philip” in Hydrophilic means “Affinity/Loving”. This coating works by absorbing the moisture which builds up on the screen and makes a transparent water layer on the lens. This water layer is arranged correctly and does not block the view.

Hydrophilic coatings are usually made by 2-types of nanoscale particles, colloidal silica, and porous organo-silicate micelles, in a polyurethane matrix.

➔ Pros:

- Saves a user from going blind due to extreme fog.

➔ Cons:

- Only works to a specific moisture level. If fog building increase, it will fail.

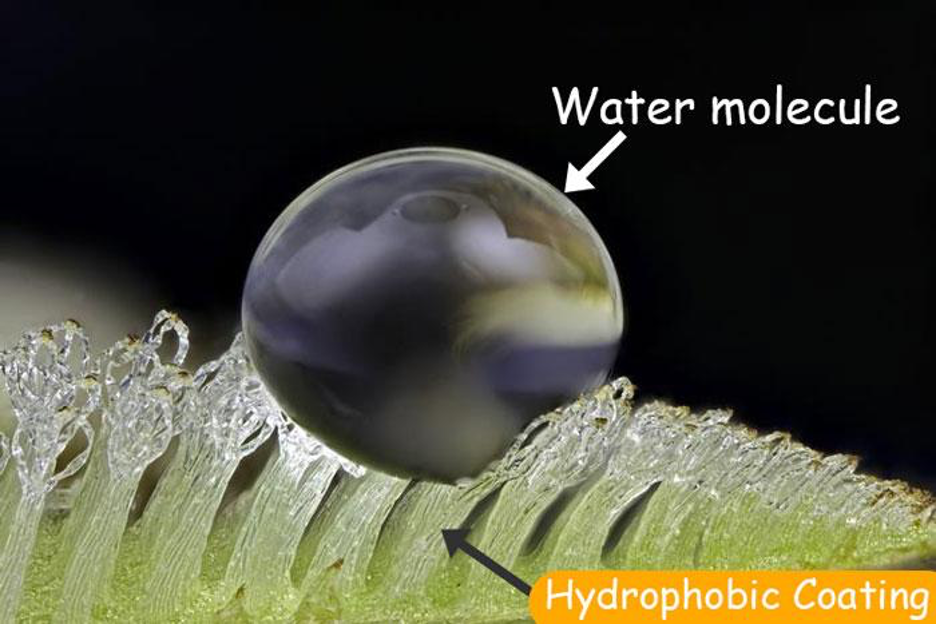

b) Hydrophobic

The “Phobic” in Hydrophobic means “fearing”. This coating works by repelling the water and slides it down as soon as fog particles build up on the lens.

Hydrophobic anti-fog coatings are made of soap-based chemicals.

➔ Pros:

- Prevents fog from forming and saves a person from an accident.

➔ Cons:

- Only works up to a certain point.

“Both Hydrophobic & Hydrophilic coatings are good, but they have limitations. Indeed all kind of Anti-Fog Coating does. That’s why proper ventilation is required to replace wet air with fresh air so moisture levels remain in the air. In addition, some premium sellers used Hydrophilic and Hydrophobic coatings in a mixture for more output.”

5) Strap

Last but not least, the strap is the part that keeps the Goggles attached to the head. The Straps of the Goggles are flexible and made out of a combination of Nylon, Polyester, & Rubber stings. The strap inside is lined with silicone beads/lines to give more friction for attachment with a helmet.

➔ Pros:

- Gives a firm attachment

➔ Cons:

6) Tear-Off / Roll-Off

The tear-off or roll-off feature is only available in Motocross Goggles. When a lot of dirt falls on the Goggles while racing on a track, it makes it nearly impossible to see, and the rider may end up in an accident. To solve that;

- One may install and tear-off thin sheets, when dirty, can be separated & thrown away, leaving new clear sheets beneath.

- Another way to install, Roll-off mechanism. In this method, two cylinders are installed at the side of the goggles; one is full with a thin sheet, other I empty. When the lens gets dirty, the empty cylinder pulls the sheet, so the dirty film from the lens is pulled away, and a new clear film comes on the lens.

The film is made from thin plastic, mostly Polyester.

➔ Pros:

- Clear the lens of dirt multiple times in a race.

➔ Cons:

- The thin sheets may distort the light and blur the vision.

The cylinders in the Roll-off mechanism probably block the peripheral view.